Wayne Bauer’s career in the grain industry spans more than 36 years. Bauer served as GEAPS International president from 2004-2005 and is co-chair of the Michigan Food & Agricultural Protection Strategy Committee, where he works with over 175 agricultural and food-related firms in Michigan and has been an active participant since 2005. Since 2007, Bauer has served on the joint U.S. Agro-Terrorism Prevention & Facility Security Committee with representatives from GEAPS/NGFA and North American Export Grain Association.

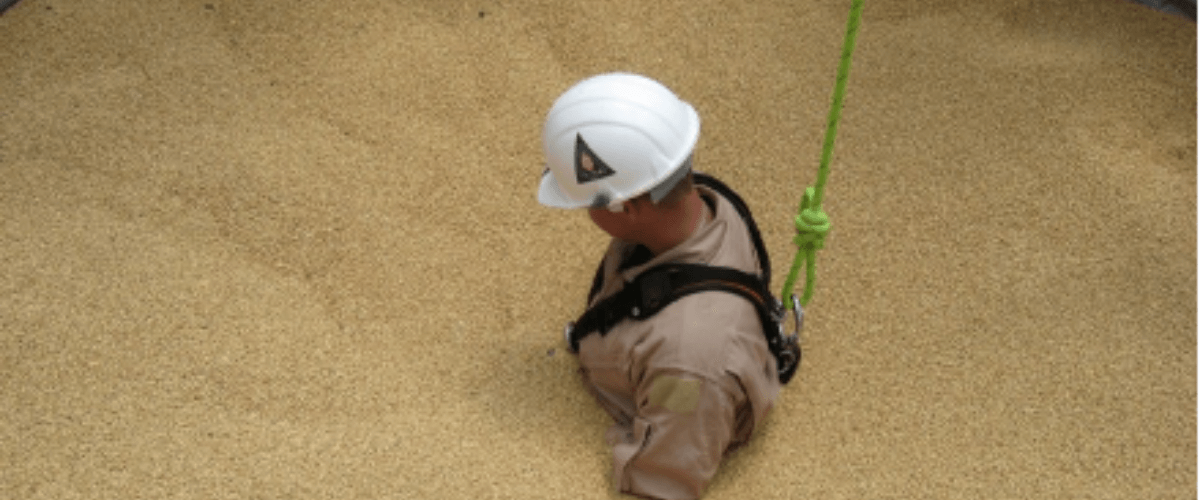

Grain Entrapment: Causes, Prevention and Rescue

GEAPS Online Learning courses are available anytime on-demand. Each course takes approximately 10 hours to complete and can be completed at any pace over five weeks. Courses must be completed within a five-week period that begins the day you register. After registering, learners will be sent a confirmation email, then you’re ready to start learning!

Cost:

$495 for members

$795 for non-members.

Course Description: This course was developed to provide students with an overview of grain entrapment causes and prevention. Topics will include: common causes of entrapment accidents, with attention devoted to how out-of-condition grain often plays a role; bin entry standards and regulations; reclaim systems; training requirements; permits and accountability; safety requirements, including air monitors and cofferdams; best management practices and safety features in new grain facilities.

Course Goals: This course aims to familiarize students with the basics of grain entrapment, from how to identify problem areas, to preventive maintenance, to different equipment and systems to prevent entrapment. By the end of the class, students should be able to identify regulations, initiatives, and standards and know how to put in place emergency plans.

Target Audience: Designed for people with responsibilities relating to grain and processing facilities, including owners and operators, elevator superintendents, location or regional managers, safety managers and anyone with a professional need to learn more about grain entrapment prevention.

Instructors:

Dr. Carol Jones is an assistant professor at OSU, specializing in stored products engineering. Her research and extension efforts focus on equipment and processes that help to maintain grain quality, profitability and safety. Her research efforts also include post-harvest technology of several specialty crops such as tree nuts, herbs, fruits and vegetables. Carol is currently with the Cherokee Strip Chapter and is heavily involved in their initiative to bring safety training and cultural development to both commercial and family farm grain storage facilities throughout the state.

Joe Mlynek is the president and safety and loss control consultant for Progressive Safety Services. Prior to forming Progressive Safety in 2009, Joe worked as a safety professional in a wide array of industries including: automotive, chemical, railcar repair, retail, metal fabrication and grain handling. Joe has a bachelor’s degree from Bowling Green State University in environmental policy and analysis and holds a certification as an occupational health and safety technologist.

The Course of Study

Lecture 1 – Introduction and Identification of Problem Areas

The purpose of this lecture is to give an overview of grain entrapment and discuss factors that can cause entrapment situations. It will cover topics such as bin construction history, changing physical characteristics of bins, the trend line for grain entrapments and deaths, grain conditioning and monitoring spoilage, best management practices, an emergency preparedness overview, the design parameters for future grain handling facilities, embracing the new paradigm shift and other applicable standards.

Lecturer: Wayne Bauer

Lecture 2 – Quality Grain Management and Safety

This lecture examines the relationship between storage, quality and entrapment. It looks at both cost factors and safety. It will cover the overall objective and dilemmas of storage, causes of spoilage, pest prevention, empty bin treatment, sanitation, coring, aeration airflow rates for dry grain, roof vents and exhaust fans and monitoring. By the end of this lecture students will understand how grain quality will keep their workplace safer.

Lecturer: Dr. Carol Jones

Lesson 3 – Government Regulations and Consensus Standards

This lecture will provide an overview of government regulations and standards and how they apply to grain-industry safety issues. It will cover regulation versus consensus standards, fall prevention and protection, work positioning and restraint systems, fall arrest systems, emergency action plans, emergency rescue procedures, and bin, silo and tank entry. This lecture also touches on government regulations for Canada.

Lecturer: Wayne Bauer

Lecture 4 – Fall Protection: Fall Arrest vs. Fall Restraint

This lecture explains the differences between fall arrest and fall restraint. It will provide information about falls and the OSHA quick card and regulations, definitions and types of fall arrest systems, how to install and use the systems and types of pulley and bracket systems available.

Lecturer: Jeff Decker, Wayne Bauer

Lecture 5 – Grain Unloading and Reclaiming

This lecture will help students understand the impact of reclaiming and unloading on entrapment. The main topics covered include: methods for reclaiming grain and industry concerns with regulations. Equipment and methods discussed include vacuum, sweep auger, paddle sweep, tractor with front end loader and conical bin.

Lecturer: Dr. Carol Jones

Lesson 6 – Training Requirements, Use of Permits and Employee Accountability

This lecture provides an overview of training and employee accountability in regards to safety. It will cover a definition of accountability including employee accountability for safety, suggestions to foster accountability and a discussion of who is accountable for safety. Also included is a definition of safe behaviors, desired behaviors, leadership behaviors and responsibilities, performance evaluations, the progressive discipline process, CSE/bin entry requirements and permits and entrant responsibilities.

Lecturer: Joe Mlynek

Lecture 7 – Grain Bin Safety Equipment

This lecture will discuss equipment utilized for safe bin conditions. The lecture will cover dangers and causes of explosions, entrapment, collapsing bins, respiratory hazards, falls and entanglement. It will also examine: safety equipment such as respiratory masks, self contained breathing apparatuses, coveralls and gas monitors; rescue and recovery equipment and how machinery guards and proper clothing can prevent machinery entanglement.

Lecturer: Dr. Carol Jones

Lesson 8 – Emergency Preparedness

This lecture will discuss the importance of being prepared for an emergency situation and of working with local fire and rescue during an emergency. After this lesson, students will be able to identify real threats, understand emergency action plans, train for emergencies, create partnerships with local fire and rescue teams, and do risk and needs assessments.

Lecturer: Bill Harp

Lesson 9 – Steel Bin Design Standards: Planning for the Future Today

This lecture will provide understanding of the necessity of steel bins, steel bin design standards and how to plan for the future. The main topics covered will be: why standards are needed, current standards and standards under review. The lecture will also discuss preparation and planning, the advantages of standards, the process of creating standards, the constraints of standards and standards presently under consideration.

Lecturer: Dr. Carol Jones

Lesson 10 – Grain Entrapment Prevention Initiatives

This lecture will give students an overview of grain entrapment prevention initiatives. This will include a history of grain entrapments and prevention initiatives, best management practices, a summary of shut down and lockout equipment requirements, how to evaluate your emergency response time and design parameters for future grain facility building.

Lecturer: Wayne Bauer